Metal is one of the main materials for custom display fixtures, you need it looks perfect, and also on-budget. To achieve the best results, the supplier needs to be correctly use right materials and production process.

The 3 main metal material is Mild Steel, Stainless steel, Aluminum.

MS: Mild Steel, SS: Stainless Steel, AL: Aluminum.

Mild Steel is one of the most crucial materials for custom store fixtures, for example, Racks, Tables, Shelves, Gondola etc. Hot-rolled and cold-rolled steels are mild steel, containing from 0.1% to 0.3% carbon. Such chemical composition makes them suitable for welding.

Mild Steel is magnetic.

The differences between hot rolled steel and cold rolled steel relates to the way these metals are processed at the mill, and not the product specification or grade. Hot rolled steel involves rolling the steel at high temperatures, where cold rolled steel is processed further in cold reduction mills where the material is cooled followed by annealing and/or tempers rolling.

The main advantages of Cold Rolled Steel:

Accurate finished dimensions

Clean surface

Greater strength properties

The main advantages of Hot Rolled Steel:

Lower cost: Hot rolled steel tends to be less expensive than cold rolled steel since it involves less processing.

Better workability: As the hot rolling process occurs at elevated temperatures, the processed material is easy to form and shape.

Tube is made from metal sheet, Square Tube, Round Tube and Elliptic Tube, so the price of tubes is little bit higher than mild steel sheet.

Here is the specification of Round Tube

Please send email to info@hicodisplay.com for specifications of Square Tube, Elliptic Tube and wires in China local market.

Round Tube | |||

Diameter(mm) | Diameter(inch) | Thickness(mm) | Thickness(inch) |

12.7 | 0.5 | 0.7-1.0 | 0.02-0.03 |

13 | 0.51 | 0.7-1.0 | 0.02-0.03 |

15 | 0.59 | 0.8-1.5 | 0.03-0.05 |

15.9 | 0.62 | 0.7-1.5 | 0.02-0.05 |

16 | 0.63 | 0.7-1.5 | 0.02-0.05 |

18 | 0.71 | 0.8-1.6 | 0.03-0.06 |

19 | 0.74 | 0.8-1.6 | 0.03-0.06 |

19.1 | 0.75 | 0.8-1.6 | 0.03-0.06 |

20 | 0.78 | 0.8-1.8 | 0.03-0.07 |

21 | 0.82 | 0.8-1.8 | 0.03-0.07 |

21.8 | 0.85 | 0.8-2.0 | 0.03-0.08 |

22 | 0.86 | 0.8-2.0 | 0.03-0.08 |

22.2 | 0.87 | 0.8-2.0 | 0.03-0.08 |

25 | 0.98 | 0.8-2.0 | 0.03-0.08 |

25.4 | 1 | 0.8-2.0 | 0.03-0.08 |

27.2 | 1.07 | 0.8-2.0 | 0.03-0.08 |

28 | 1.1 | 0.8-2.0 | 0.03-0.08 |

28.6 | 1.12 | 0.8-2.0 | 0.03-0.08 |

30 | 1.18 | 0.8-1.8 | 0.03-0.07 |

31.8 | 1.25 | 0.8-3.0 | 0.03-0.11 |

32 | 1.26 | 0.8-3.0 | 0.03-0.11 |

34 | 1.33 | 0.8-3.0 | 0.03-0.11 |

37.5 | 1.47 | 0.8-2.0 | 0.03-0.08 |

38 | 1.49 | 0.8-3.0 | 0.03-0.11 |

38.1 | 1.5 | 0.8-3.0 | 0.03-0.11 |

40 | 1.57 | 1.0-3.0 | 0.04-0.11 |

42 | 1.65 | 1.0-3.0 | 0.04-0.11 |

45 | 1.77 | 1.0-3.0 | 0.04-0.11 |

48 | 1.88 | 1.0-3.0 | 0.04-0.11 |

50 | 1.96 | 1.2-3.0 | 0.05-0.11 |

50.8 | 2 | 1.2-3.0 | 0.05-0.11 |

60 | 2.36 | 1.4-3.0 | 0.06-0.11 |

63.5 | 2.5 | 1.4-3.0 | 0.06-0.11 |

65 | 2.55 | 1.4-3.0 | 0.06-0.11 |

70 | 2.75 | 1.0-2.0 | 0.04-0.07 |

76 | 2.99 | 1.4-3.0 | 0.06-0.11 |

76.2 | 3 | 1.4-3.0 | 0.06-0.11 |

Other dimensions of tube can be custimized, but MOQ minimum order quantity is 3-10 tons. No MOQ for regular di mensions, and only 1 week lead-time.

The following data is GA equivalent to mm as stated in the table:

Gauge(GA) | Mild Steel thickness(Inch) | Mild Steel thickness(mm) |

3 | 0.2391 | 6.073 |

4 | 0.2242 | 5.694 |

5 | 0.2092 | 5.313 |

6 | 0.1943 | 4.935 |

7 | 0.1793 | 4.554 |

8 | 0.1644 | 4.175 |

9 | 0.1495 | 3.797 |

10 | 0.1345 | 3.416 |

11 | 0.1196 | 3.037 |

12 | 0.1046 | 2.656 |

13 | 0.0897 | 2.278 |

14 | 0.0747 | 1.897 |

15 | 0.0673 | 1.709 |

16 | 0.0598 | 1.518 |

17 | 0.0538 | 1.366 |

18 | 0.0478 | 1.214 |

19 | 0.0418 | 1.061 |

20 | 0.0359 | 0.911 |

21 | 0.0329 | 0.835 |

22 | 0.0299 | 0.759 |

23 | 0.0269 | 0.683 |

24 | 0.0239 | 0.607 |

25 | 0.0209 | 0.531 |

26 | 0.0179 | 0.454 |

27 | 0.0164 | 0.416 |

28 | 0.0149 | 0.378 |

29 | 0.0135 | 0.342 |

30 | 0.0121 | 0.307 |

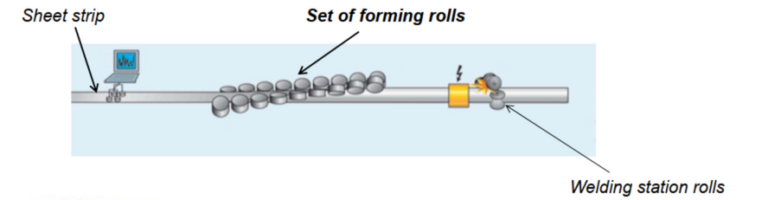

Let’s look at the process of roll forming.

Roll forming is a simple yet efficient metal forming process, ideal for even the most complex shapes. The process involves a roll forming mill and starts at the coil feeder, where material – typically coiled steel – enters the line. Some applications require a pre-piercing operation prior to being roll-formed. Subsequently, the strip of sheet metal is passed through a set of forming rolls. Each forming roll only bends small parts of the bend until the final shape is obtained. This progressively shaping method prevents springback from occurring.

Depending on the requirements that a product has to meet, roll forming mills can be up to 100 meters long. Roughly at the middle of the roll forming mill, a welding station is used to permanently join the two endings of the sheet metal together, so that the tube is closed. Compared to tube bending, tube forming or roll forming allows smaller radii. Furthermore, metal thickness does not change significantly except for a slight thinning at the bend radii. The process of roll forming is used to form a wide variety of cross-section profiles. Even though an open profile is most common, closed tube shapes can be crafted as well.

Stainless steel is a metal alloy, made up of steel mixed with elements such as chromium, nickel, molybdenum, silicon, aluminum, and carbon. Iron mixed with carbon to produce steel is the main component of stainless steel. Chromium is added to make it resistant to rust. Stainless steel is not magnetic.

No Rust and Long-Lasting.

In China, we use 201 and 304 for store fixtures. 304 is price higher than 201. 304 is totally no rust when use in stores for long lasting, and 201 maybe rust when used in wet environment.

Stainless steel is non-porous, which means it resists lingering germs and bacteria better than wood or plastic surfaces. It can be used for many years, and easy to clean.

Looks Morden

You can use stainless steel for checkout counter, tables or wall system. People like the neutral look of stainless steel.

Can Be Use For Valuum Plating

If you need golden, brozeen or other morden colors for shopfittings, it is best to choose vacuum plating for it. Powder coating and printing can not match it.

Hot rolled pickled and oiled steel are steel products that undergo descaling and pickling. It is a process of eliminating the iron oxide scale layer by applying hydrochloric acid to the surface. Oxygen exposure produces surface contaminants, and unwanted elements appear on the steel.

Surface quality and service requirements (mainly cold forming or stamping properties) intermediate products between hot and cold rolled sheet are ideal substitutes for partial hot rolled and cold rolled sheet. Compared with hot rolled plate, the advantages of pickling plate mainly lie in: 1) good surface quality, because the hot rolled pickling plate removes the surface oxidation sheet, improves the surface quality of steel, and is convenient for welding, oiling and painting. 2) High dimensional accuracy, flat, can make certain changes in the plate shape, so as to reduce the deviation of unevenness.

Galvanized steel refers to the ordinary carbon construction steel after galvanizing can effectively prevent steel corrosion and rust to prolong the service life of steel. Among them, galvanizing is divided into electro-galvanizing and hot-dip galvanizing.

There is no too much demand for galvanized sheet on custom store fixtures.

Aluminum is a lightweight silvery white material, it is durable and funicational. It can be use for stallwall panel. Alumiunm panel can be powder coating, printing and anodizing.

Another key factor for cost saving is the right surface finishings for your displays.

It can be use to steel sheet, tube, wire and aluminiunm surface for store fixtures. and it is long-lasting, most of custom display fixtures are using that powder coating finish.

There are powders for indoor application and outdoor application, and not all colors is same price. Outdoor application is price higher than Indoor application. Gold and sliver color is price higher than other colors.

The max size of your rack of parts is 800mm wide, 1550mm tall, and 3300mm long to our powder coating line.

We also have a individual Powder Coating Oven, the max size is 2000mm wide, 1800mm height, and 4000mm long.

Usually, we use mild steel for podwer coating.

The best tools for the job in powder coating include equipment for the pre-treament, application, and curing stages of a job.

Pre-treatment

Chemical wash station – Oil, grease, chemicals, or solvents needs to be removed from the surface before any other step, even if you are sandblasting. If there is still grease present, sandblasting can force it to penetrate the metal, causing bigger problems down the line. Chemicals or detergents are used at a wash station, and these can be manual or automated. An automated wash station takes the part through cleaning, rinsing and prep via a conveyor.

Sandblasting gun and blast room – One of the most commonly used pieces of pretreatment equipment is the sandblasting gun. Abrasive media like grit, soda, or steel shot (not sand) is propelled at the substrate using compressed air. The material blasts and abrades the debris, rust, or old paint from the surface, while also creating a slightly roughened surface texture to promote adhesion.

Dry-off oven – Similar to a curing oven, a dry-off oven evaporates any remaining cleaning chemicals from the surface.

Coating

Powder coating is a dry finishing process in which free-flowing, thermoplastic or thermoset powder material, rather than a liquid suspension, is applied to a surface, melted, and then allowed to dry and harden into a protective coating. Typically, the powder is applied via electrostatic spray deposition (ESD) to an electrically grounded metal substrate. Once the powder coating is completely applied to a part, it is then heat cured in an oven until the powder melts and flows together. As the part dries and cools, the cured powder forms a smooth, hard finish.

Preheat/Dry

Time and temperature are the critical considerations for powder coating curing, but they are not set in stone. A longer period at a lower temperature may work just as well as a shorter period at a higher temperature. The curing temperature of the powder refers not to the air or emitter temperature but the temperature of the substrate. Temperature needs to be rigorously maintained and controlled.

Convection powder coating oven

Gas or oil-fired heaters are used to heat air which is then circulated through the oven space. These ovens can be direct or indirectly fired; In indirectly fired ovens the hot air from combustion travels through a heat exchanger to remove the combustion products and provide clean air.

Our production capacity is 1200 square meters per day.

Clear powder coating

Clear powder coating is simply the process of spraying clear coat over powder coat. This layer of clear can be applied over any powder coat color, and the main benefit that can come from this is an improvement of gloss. When you clear powder coat, you will notice that the surface will add an element of sparkle. Some clients like the raw surface of metal, so that the metal surface should be perfect, no rust, no scratches, usually, we will use cold roll steel for clear powder coating.

Please send me a color chip, we can 100% match it.

Chrome plating (less commonly chromium plating) is a technique of electroplating a thin layer of chromium onto a metal object. A chrome-plated item is called chrome. The chromed layer can be decorative, provide corrosion resistance, ease of cleaning, or increase surface hardness. Sometimes, a less expensive imitator of chrome may be used for aesthetic purposes.

We use cold roll steel for chrome,

Nickel plating is price higer than Galvanizing, but close to Chrome.

Nickel plating process is similar to chrome plating.

Panel, wire and tubes can be chrome plating, nickel plating and galvanizing.

Usually there is only one color for chrome plated items, and we will use valuum plating for glod plating or other colors.

No need to worry about the size of your store fixtures, we can finish chrome plating perfectly.

Chrome is price higher than powder coating.

Both powder coating and chrome need a leck hole to hing on machine line. for some small items, like a very small hook, roller plating is a cost effective way,

Chrome plating process for display fixtures:

Step 1: Inspection

In the initial inspection, the mild steel is assessed to evaluate its condition ahead of the chroming process. Here the inspector will note any evidence of corrosion, pitting, marring, damage, cracking or flaking of the material. Presence of these phenomena will be taken into account and may influence the decisions taken at various steps along the re-chroming process.

Step 2: Grinding & Stripping

Before chrome applied, the mild steel must be Grinding & Stripping. However, this must be done in such a way to preserve the steel underneath and without reducing the dimension of the raw material itself. Doing so would result in raw material that exceeds cylinder tolerances. There are two methods for removing this material. These are: grinding and stripping.

Electrolytic Stripping:

During stripping, the metal part is placed in a reverse-electrolysis tank. This process is essentially the opposite of electrolytic plating. Whereas chrome plating applies a positive current to a chrome solution – which adheres chrome molecules to the surface of the steel, reverse electrolysis does the opposite. A negative current is applied to the solution and chrome molecules separate from the surface.

Grinding:

The other method is through grinding with large stone grinding wheels. The metal part is centered on a large lathe-like grinding machine. The metal part is rotated at a constant rate and brought into contact with the spinning stone grinding wheel. The friction wears away the old material much like sanding varnish from a piece of wood (except with more sparks). This technique requires a high level of skill and experience from the operator who must instinctively gauge how much pressure to apply to remove the layer of chrome without damaging the steel underneath.

Step 3: Cleaning & Masking

Before preparing the cylinder mild steel to be placed in the bath of chromium solution, the steel must be thoroughly cleaned and any debris or contaminants must be removed. Failing to do this could result in undesirable anomalies during the plating process such as pitting and pinholes or flaking and peeling of the chrome during the life of the cylinder. At this stage, the metal part is cleaned and the ends are masked to ensure a neat and professional final product.

Step 4: Plating

The process of electrolytic plating is a well-known one. we use it in chrome plating for racks, tube, hangers etc. In this process, objects to be plated are placed in a bath containing a solution of dissolved metal molecules. Electrodes are attached to the object to be plated and a positive current is applied to the solution. As the current runs through the solution and out through the electrodes, it causes the dissolved metal particles in the solution to be attracted to and adhere to the metal surface of the metal.

Step 5: Surface Finishing

With a fresh new layer of chrome applied, it’s time for the metal to be finished. This takes place in two stages in which the chrome coating is reduced to the exact, required thickness and then polished to achieve the perfect surface finish. These stages are post-grinding and linishing.

Step 6: Inspection

Before the chroming job is complete, it must pass the unforgiving gaze of the inspector. Armed with an experienced eye and digital surface thickness and roughness measurement devices, the metal part is inspected for the quality of the chrome job, and to ensure there are no defects.

Step 7: Wrapping

As a final step in the process, the completed metal part is wrapped securely in cardboard and protective plastic. This is done to safeguard the perfect chrome surface while it is transported back to the repair division.

Vacuum titanium plating is an ideal surface color coating technique for stainless steel casting, which is operated under the condition of vacuum. With the arc discharge, cathode titanium target was used as the evaporation source, through the arc discharge between the titanium target and the anode, the titanium target is evaporated to form ion.

Both 210 and 304 stainless steel can be use for vacuum.

Pre-treatment process

Decoating, blasting, polishing, passivating, cleaning, clamping.

Coating process

Evacuation, heating, leak rate test, bombardment cleaning, coating, cooling out.

Post-treatment

Why cooling it?

After the coating process is completed, the temperature of the vacuum chamber is up to 500°C. If it is evacuated without cooling, the surface of the high-temperature workpiece that is not plated will become blue because of the reaction with the air.

How to cooling?

Vacuum environment is the most important factor affecting the final coating quality. Before the coating, the pressure rise rate must be performed to ensure that the vacuum environment conditions meet the coating standard.

When working in large scale projects, efficiency is one of the most important traits your business can have. Efficiency doesn’t mean cutting corners in order to finish jobs quickly; instead, it means spending exactly the right amount of effort on a project with little waste and lower production cost.

A press brake is the most commonly used that make metal fabrication easier. Basically, this device bends metal into different shapes. It takes up quite a bit of space, but you’ll find the investment is worthwhile.

Again, press brakes allow you to bend metal in many ways. This feature is crucial for metal fabrication because many automated machines do a limited variations of bends and shaping maneuvers. We can also use toolings for bending and punching.

Mostly, we can produce without tooling for prototypes, and 5-7 days lead-time for new toolings.

What is MIG & MAG welding?

Metal inert gas (MIG) welding is an arc welding process used to join two base materials. A continuous wire electrode is heated and an electrical arc forms between the electrode and the base metal. The welding gun feeds a shielding gas — typically argon or carbon dioxide — alongside a solid wire electrode to protect the welding pool from contaminants.

What is TIG welding?

TIG or tungsten inert gas welding is one of the most popular ways to weld metals in a seamless way. It uses the same principle as arc welding does, the difference being that TIG welding uses a non-consumable electrode.